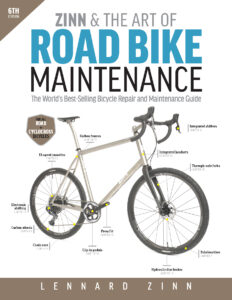

Zinn and the Art of Road Bike Maintenance Supplementary Material

5-19 Rehabilitating Shimano STI Integral Brake/Shift Levers

If you have a jammed Shimano STI shifter, you cannot go into the mechanism and replace parts because Shimano doesn’t sell the internal parts separately. Beyond that, opening the mechanism voids the warranty.

In the 5th edition of Zinn & the Art of Road Bike Maintenance, I advise trying an injection of aerosol chain lube to free up a sticky mechanism (pages 93–94). If that does not work, you can replace the entire shifter unit of two blades and internal ratchet (Fig. 5.38). Note that this approach may be false economy; you save the lever base, rubber hood, and band clamp, but you generally pay more than half the cost of a pair of levers for a single blade assembly. But if you find a bargain somewhere, here’s the procedure:

1. Remove the shift and brake cables and the brake-cable hook from its notches.

2. With a 2mm hex key, remove the setscrew holding the pivot axle (Fig. 5.38) in place under the lever. Expect it to make noise while being unscrewed and for it to be hard to remove. There is a lot of threadlock compound on it to keep it from vibrating loose.

3. Push out the axle with a blunt nail struck by a hammer, and catch the spring.

4. Pull off the old blade assembly and insert the new blade assembly.

NOTE: If you have a lever that is Flight Deck–computer compatible, you will need to unscrew the cover on the inboard side of the lever under the gum hood and push the end of the wiring harness up through the lever as you pull off the blade. Fish the wires of the new blade back in the same way, and replace the cover to hold the little rubber part and the four terminals in place.

5. Replace the return spring and axle. The return-spring hook goes in the hole adjacent to the cable-hook notches, and its other end must sit on the shelf adjacent to the setscrew, not down in the wide notch in the lever body. Line up the rounded groove in the axle with the setscrew.

6. Put some threadlock compound on the setscrew and screw it back into place.

7. Replace the cable hook into its notches.

5-25 Cyclocross preparation

On a cyclocross bike with a single chainring, why carry the weight of the shift mechanism in your left brake lever if it’s never going to be used? You could run SRAM CX1, which has a dedicated left lever devoid of a shift mechanism. Otherwise, if you were to replace your left brake/shift lever with a simple brake lever, its shape would not match that of the right lever. However, if you pull the shifter mechanism out of your existing left lever, it becomes a superlight brake lever that is shaped just like the other lever; these instructions describe how to do exactly that for Campagnolo and SRAM levers. The section and page references below apply to the 5th edition of Zinn & the Art of Road Bike Maintenance.

REMOVE SHIFTER MECHANISM FROM LEFT CAMPAGNOLO ERGOPOWER LEVER

Depending on which type of Ergopower (EP) lever you have, follow the overhaul instructions in 5-20, 5-21, or 5-22 (pages 94–104) until you have the lever completely disassembled. Remove the two bearings and spacer between them from the center of the plastic lever body. Then, instead of reinstalling all of the shifter parts, just replace the brake lever. Now you have a really light lever that matches your right lever in shape and feel.

REMOVE SHIFTER MECHANISM FROM LEFT SRAM DOUBLETAP LEVER

As part of its 1 x 11 cyclocross group, SRAM’s superlight CX1 left lever has no shift mechanism, and its elimination has reduced the interest among top competitors to disembowel their SRAM left shift/brake levers. Prior to the advent of CX1, however, gutted SRAM left levers were common at cyclocross races. Pulling the guts from the lever is not a recommended or authorized procedure by SRAM. But if you want to give it a try, here are the instructions. And if you store the 35–45 grams’ worth of parts you remove in a safe place, you can reinstall them if you change your mind in the future and want a front derailleur after all.

DISASSEMBLY

- Disconnect the brake and shift cables at the brake caliper and front derailleur.

- Pull the brake lever. Push the brake cable out of it and remove it.

- Remove the shift cable. Click the shift lever with the short-throw, single-click downshift motion to the fully released (small chainring) cable position. Peel up the skirt of the lever hood and push the shift cable out of its access hole on the inboard side of the lever and remove it.

- Remove the hood. Squirt rubbing alcohol on the lever body and inside the hood. Twist the hood around on the slippery alcohol layer, and slide the hood off over the top or bottom.

- Remove the access cover. With a small Phillips screwdriver fully inserted into the head of each screw to avoid stripping it, remove the three screws holding the inboard shifter mechanism access cover on, and remove the cover itself.

- Push out the brake lever’s pivot pin by tapping it out with a blunt nail and a mallet. To prevent the edge of the lever from flexing outward, support the lever body near the pin as you tap by holding the lever body flat on a block of wood that has a drilled hole under the pin. Because of the bowed shape of the lever body, it’s probably easier to place the outboard side over the hole in the wood block and tap the pin out from the inboard side. Pull off the brake lever, with its plastic pivot bushings still in place.

- With the small Phillips screwdriver, remove the shifter pivot pin retaining screw from the outboard side of the lever body or simply unscrew it until you can see that its tip is no longer impeding the shifter pivot pin. You can see the bottom of the pin and retaining screw across its end from the bottom side of the lever body; look just forward of the handlebar band clamp.

- Remove the pivot pin. Find the top of the shifter pivot pin (it goes straight up through the shifter mechanism and protrudes inside the lever body behind the top of the shift lever). With the short end of an L-bend 2mm hex key, push the pivot pin down so it protrudes enough from the bottom of the lever body that you can pull it completely out with your fingers (or, if necessary, a pair of pliers).

- Remove the shift lever (along with its attached assembly of pivot body, pawl, and three springs). Rotate it inward to release it from the spool, then lifting it out of the lever body. Put the assembly in the container where you’re keeping all the parts.

- Push the circlip (C-shaped retaining ring) off the top of the pawl pivot pin located at the very front of the lever body. Use a knifepoint or a sharp pick.

- Push the pawl pin out the bottom of the lever body while keeping parts from flying out of the mechanism with your thumb. Use the short end of the L-bend 2mm hex key.

- Pull the pawl, pawl return spring, spool (large metal piece with the plastic base), and spool return spring out of the lever body.

REASSEMBLY

- Replace the brake lever, including its plastic bushings, into the lever body. Line up the holes in the lever and body; hold the parts together by pushing the brake lever pivot pin back in partway by hand. The pin is symmetrical; you can push it in from either side.

- Install the brake lever pivot pin. Set the end of the pin on a wooden surface and tap the side of the lever body down onto it with the mallet until the pin is fully inserted with the same amount protruding on either side.

- To reinforce the lever body vertically against impacts, you can reinstall the shifter pivot pin from the bottom and tighten its retaining screw from the outboard side of the lever body to hold it in place. This is probably worth doing; it adds only 5 grams.

- Replace the hood. Lube the inside of the rubber hood with rubbing alcohol and slide it back onto the lever body

5-42 Drivetrain Compatibility Issues Between Brands, Models, and Speeds

This section amplifies the information on pages 115–116 of the 5th edition of Zinn & the Art of Road Bike Maintenance. Table 5.2 (page 116) provides a complete rundown of rear shifting specifications, including cable pull, shift ratio, and cog pitch, for Campagnolo, Shimano, and SRAM systems from six-speed through 11-speed set-ups.

The number of rear cogs on a road bike keeps going up every few years. But does any of the old stuff work with any of the new stuff? And can you mix Shimano, SRAM, Campagnolo, and FSA drivetrain parts?

If you have resolutely stuck with your old frictional down-tube shifters, you can let Campagnolo and Shimano throw however many cogs they want at you, and you will still be able to shift. That old Campagnolo Nuovo Record shifter and derailleur shifted the chain across 5 cogs, and it will probably work on 11 cogs! Modern indexed systems shift more precisely, but they don’t offer that kind of flexibility.

Compatibility problems occur because the spacing between cogs and the chain required narrows as the number of cogs goes up. Also, the rear hub axles have gotten longer. The spacing between rear dropouts (and hence the rear axle “overlock” length dimension) was at 120mm during 5-speed days, was 126mm during the 6- and 7-speed era, is 130mm for 8-, 9-, 10-, and 11-speed hubs, and is 135mm for disc-brake hubs.

Threaded freewheels

The 5-, 6-, and 7-speed era marked the beginning of the transition from freewheels that threaded onto the rear hub to cassette freehubs built into the hub onto which separate cogs could be installed. With some minor exceptions, freewheels were completely compatible with every hub, since nearly all shared the same threading. Spacers sometimes had to be moved around from one end of the axle to the other to prevent the chain from dragging on the frame in the smallest cog. And, of course, you had to get a longer axle and re-dish the rear wheel when frames went from 120mm to 126mm rear spacing. But that was about it.

Freewheels did appear with eight speeds, so you could still space your old hub one more time with a new axle to 130mm. But freewheel makers threw in the towel when we hit nine speeds.

Five-speed freewheel cogs were spaced farther apart than current cogs, and there was no consistency of cog spacing between brands. There did not have to be, since the rider was manually lining up the derailleur with each cog. You were also lucky to have a 13-tooth first cog, rather than the 14-tooth that the previous generation saw as a high gear.

The first SunTour 6-speed freewheels were called “Ultra 6” and had narrower spacing between cogs (and a narrower chain) so they would fit on a 120mm rear hub. Not everyone embraced narrowness, but many riders wanted the 12-tooth cogs that SunTour offered. Splitting the difference, many frames of the era (especially Italian ones) were built with 126mm rear spacing and equipped with 6-speed freewheels with cogs set at the old wide spacing. SunTour answered with “Ultra-7” narrow-spaced freewheels and chains. Sedis started making narrow chains as well, and narrow spacing became the standard, carrying on into 8-speed.

Cassette freehubs

Shimano’s spacing between cogs has narrowed from 3.70mm for 5- and 6-speeds to 3.10mm for 7-speed, 3.00mm for 8-speed, 2.56mm for 9-speed, 2.35mm for 10-speed, and 2.18mm for 11-speed. Shimano freehubs appeared around 1980 and accepted six speeds widely spaced (at 3.70mm apart) on a 126mm hub. The first five cogs were splined to fit on the splined freehub body, and the last cog threaded on. Shimano Uniglide chains were wide and had a bent-plate configuration. Shimano began making its first indexed shifting systems in the mid-1980s as well.

When SunTour introduced narrow Ultra-7 freewheels in the early 1980s, Shimano countered with wider freehub bodies that fit seven widely spaced cogs (at 3.70mm apart) and the wide Shimano chain.

In the second half of the 1980s, Shimano succumbed to the rising popularity of narrow chains and made narrow bent-plate (Uniglide) chains. Its new freehub body was the old 6-speed length, and it fit seven narrowly spaced cogs (at 3.10mm apart). But the new cogs would not fit on the old freehub bodies because a lockring now secured the cogs instead of a threaded small cog, and one spline groove was wider than the others.

The 1990s began with Shimano’s introduction of 8-speed cogsets with 3.0mm cog spacing. Shimano had dictated that frames now had to have 130mm rear ends to accommodate new hubs with wider freehub bodies. Its one-wide-spline arrangement and threaded lockrings continued, but eight cogs would not fit a 7-speed body.

This set the stage for 9-speed Shimano cogsets, which had narrower (2.56mm) spacing and a narrower chain, and fit on 8-speed freehubs at first. But the desire for an 11-tooth cog forced the reduction of the freehub diameter by removing the outboard 2–3mm of spline ridges, which required new hubs (unless you were handy enough with a grinder to knock off the last couple of millimeters of the spline ridges).

With the advent of 10-speed cogs, Shimano’s freehub body changed again, utilizing deeper spline valleys so that soft aluminum freehub bodies would not get torn up by the cogs. The outer diameter of the bottom of the spline valleys in the freehub body remained unchanged, so 10-speed cogs will fit on 9-speed freehub bodies. But 9-speed Shimano cogs will not fit Shimano 10-speed freehub bodies. Fortunately, by 2008 Shimano had abandoned the deep-spline freehub bodies and was back to using the same freehub dimensions that it has used since the introduction of nine speeds.

When Shimano went to 11 speeds, the width of the cogset increased by 2mm, so 11-speed freehub bodies not only became 2mm wider than 9/10-speed ones, they became non-interchangeable onto 10-speed wheels. Mavic 9/10-speed wheels, however, already had a 2mm wider freehub body and came with a spacer to put behind the largest cog; simply removing the spacer makes it 11-speed compatible.

As for SunTour, Mavic, and Campagnolo, all began making freehub bodies and cogs with their own spline configurations, and only Campagnolo’s systems survived the shakeout. SunTour disappeared completely from the road market, while Mavic went with the flow, making Shimano- and Campagnolo-compatible hubs, wheels, and cogs. Other hub and wheel makers followed suit.

Campagnolo, the great, reliable, and unchanging bastion of compatibility and small parts availability in the 1970s and early 1980s, changed its 8-speed freehub body when it came out with nine speeds. Campagnolo 9-speed freehub bodies have deeper splines that do not fit Campy 8-speed cogs, but its 10- and 11-speed cogsets do fit on the Campy 9-speed freehub bodies. The 5.9mm to 6.1mm-wide 10-speed chain allows 10 cogs to fit in the same space that used to accept only 9 with the wider 9-speed chain and cogset, and now the even narrower 5.4mm-wide 11-speed chain allows 11 cogs to fit in that same space. The thickness of the spacers on either side of each cog has come down to 2.2mm with 11-speed, whereas the width of each chain roller and thickness of each cog have stayed the same. The tooth-to-tooth distance is 4.55mm on Campagnolo 9-speed, 4.15mm on Campagnolo 10-speed, and 3.9mm on Campagnolo 11-speed.

SRAM, Shimano, and FSA 10-speed cogs fit on all Shimano-compatible 9- and 10-speed freehub bodies other than Shimano 10-speed aluminum ones (only Shimano 10-speed cogs fit on those). All of these 9- and 10-speed cogsets will also fit on Shimano/SRAM 11-speed freehubs, but since the freehub body is 2mm wider, you will need a 2mm spacer behind the largest cog.

Chainrings

The spacing between chainrings generally gets narrower as the number of cogs at the rear increases, but this is not necessarily the case. If you have upgraded piecemeal, you may find your 9-, 10-, or 11-speed chain falling between the two chainrings held over from an earlier 7- or 8-speed system. The narrow chain will generally slip uselessly as you pedal, but it can jam between the rings as well, causing all sorts of expensive havoc.

Chainring teeth become closer together either by reducing the thickness of the chainring mounting flats on the crank spider arms or by offsetting the teeth to one side of the chainring. Shimano 7-, 8-, 9-, and 10-speed spider arm mounting tabs are all the same thickness, but the teeth on Shimano 9- and 10-speed chainrings are offset toward each other. The tab thickness on 11-speed Shimano cranks is irrelevant, because with a four-arm spider, only Shimano’s 11-speed chainrings fit them.

Campagnolo’s spider arms got thinner when going from 7-speed to 9-speed, but the chainring teeth got offset going to 10- and 11-speed, and the spider arms stayed the same as 9-speed. You can upgrade a Campagnolo 9-speed crank to 10- or 11-speed by changing the rings.

In general, I have encountered no problems using 9-speed cranks and chainrings of any brand with 10-speed drivetrains from Campagnolo, Shimano, or SRAM. Nor have I had any trouble using 10-speed cranks with 11-speed drivetrains.

Compact-drive double cranks have smaller chainrings, with tooth counts like 34–48, 34–50, 36–50, or 36–52. These cranks have a 110mm bolt circle diameter (BCD), rather than the 130mm BCD of Shimano/FSA/SRAM or the 135mm BCD of Campagnolo. With the smaller curvature to the chainrings, standard front derailleurs did not always work well on compact cranks, although recent derailleurs from Shimano, Campagnolo, and SRAM are designed to work on both. Campagnolo’s CT and IRD and FSA compact front derailleurs were designed for compact cranks.

Shifting compatibility within brands

The rear derailleur’s shift-activation ratio—the amount of lateral movement of the rear derailleur divided by the amount of cable pull to generate that amount of lateral movement (i.e., the number of millimeters of lateral displacement of the rear derailleur per millimeter of cable pull)—is built into the derailleur. And the cable pull—the amount the cable moves with each click—is built into the shifter. Cog pitch is the distance from the center of one rear cog to the center of the next; it is equal to the thickness of a cog (other than the largest or smallest cog) plus the thickness of the spacer separating it from the adjacent cog. Cog pitch decreases as the number of cogs increases. Shift-activation ratios, cable pull, and cog pitches vary not only with the number of rear cogs but also from brand to brand, and even sometimes from model to model within a brand.

While compatibility between brands has generally reduced over time, the exception is with 11-speed cassettes. Since there are so many cogs that have to fit in the same amount of space, the cog pitch of all brands of 11-speed cogs is essentially the same. This means that you can interchange wheels with Shimano, SRAM or Campagnolo 11-speed cassettes on them onto any bike with an 11-speed drivetrain on it.

Campagnolo 9-speed (2nd-generation), 10-speed, and 11-speed derailleurs have the same shift-activation ratio, so you can use, for example, Athena 9-speed Ergopower shifters with a Veloce 9-speed rear derailleur, Mirage front derailleur, Record 9-speed cogs, Chorus crank, and Centaur hub. Or, you can use any Campagnolo 10- or 11-speed rear derailleur with a Campy 9-speed shifter and cogs. Similarly, any Campy 11-speed rear shifter and cogset will work with any Campy 10-speed rear derailleur.

Shimano components have more interchangeability exceptions. The shift-activation ratio for 7-speed and 8-speed Dura-Ace rear derailleurs was different from all other Shimano rear derailleurs, mountain or road. Put another way, you could use any Shimano shifter you wanted with any Shimano derailleur, except that Dura-Ace rear shifters were only compatible with Dura-Ace rear derailleurs.

With the advent of 9- and 10-speeds, Dura-Ace got the same shift-activation ratio as other Shimano rear derailleurs, so now all Shimano road rear derailleurs and shifters worked together. However, 10 speeds on mountain bikes brought a different shift-activation ratio; Shimano 10-speed MTB Dynasis rear derailleurs are incompatible with 9-speed shifters or any other Shimano shifter that came before. Shimano 11-speed road rear derailleurs have yet another shift-activation ratio, and it is different from Shimano 11-speed (and 11-speed) mountain-bike rear derailleurs.

Compatibility is more of an issue with Shimano front derailleurs. The 11-speed long-arm Shimano front derailleurs are incompatible with any prior Shimano shifter. And Shimano short-arm derailleurs are not all compatible, either; when the Dura-Ace 7900 front shifter with zero trim premiered in 2009, it featured a new shift-activation ratio and wouldn’t work well with the prior Dura-Ace 7800 10-speed front derailleurs, or those of any other model. Ultegra 6700 and 105 5700 front shifters didn’t adopt the 7900 cable-pull length nor that of pre-2009 shifters, but the differences are small enough that you can generally mix and match 10-speed front derailleurs and shifters from Shimano component lines and adjust them to work acceptably. If you try to use a road STI shift/brake lever with a Shimano mountain bike front derailleur (you might do this for a triple on a hybrid bike, for instance), it won’t work well.

All SRAM Red, Force, Rival, and Apex components are interchangeable, and all SRAM road shifters work with all 10-speed SRAM mountain bike rear derailleurs.

Shifting compatibility between brands

Until the advent of 9-speeds, a Campagnolo cogset did not shift acceptably on a Shimano indexed drivetrain, and vice versa. But the limited amount of space available for nine speeds brought Shimano’s and Campagnolo’s cog spacing close enough that rear wheels could be switched back and forth between the two with decent shifting performance—not as good as you would get if you paid big bucks, but acceptable for normal riding and for wheel changes during races. Neutral-support vehicles only had to stock one variety of 9-speed wheels to cover every rider in the peloton.

Of course, 10-speed systems changed all of that again. For instance, in a Shimano 10-speed drivetrain, a Campy 10-speed cogset shifts acceptably in maybe 8 of the 10 gears, the 9th cog just barely, and the 10th cog not at all. Shimano 10-speed cogsets work flawlessly in SRAM road drivetrains and vice versa.

The Mavic Zap electronic shifting system was designed for Shimano 8-speed systems, and Mavic Mektronic electronic was built for Shimano 9-speed systems, but it works decently on Campagnolo 9-speed cassettes as well.

As for front derailleurs and cranksets, mixing parts seems to cause few problems as long as you use parts designed for the same number of speeds. Campagnolo and Shimano road front derailleurs and cranksets often work fine with each other’s road shifters.

Chains

Any 8-speed chain works on any 7- or 8-speed system. All 9-speed chains work with all 9-speed systems. For 10-speeds, you’d better stick with a 10-speed chain meant for that system, and you’d certainly better keep 11-speed chains with 11-speed cogsets. Experimenting among chain brands is fine.

Generally, 7- and 8-speed chains are 7.0–7.2mm wide; 9-speed chains are 6.5–6.7mm wide; 10-speed chains are 5.84–6.1mm wide; 11-speed chains are 5.46-5.74mm wide.